Made by Welders

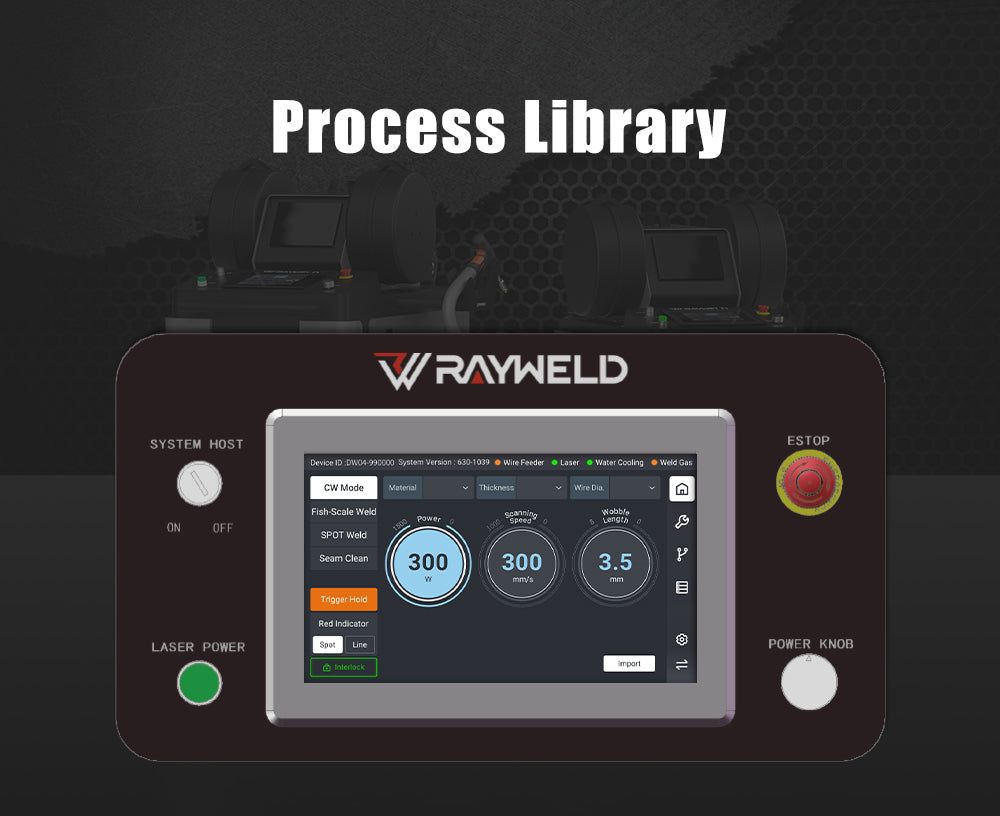

100+ Presets. Zero Guesswork.

Rayweld comes with 300+ preloaded presets for welding and cleaning, optimized for a wide range of metals and applications so you get perfect results from the very first weld.

And when you’re ready, create custom presets with a single touch, tailoring the system to your exact production needs for maximum speed, consistency, and flexibility.

Switch Materials. Keep Moving.

The uniquely engineered dual-wire feed system empowers welders to change between different filler materials in seconds—no downtime, no hassle. Whether you’re moving from stainless steel to aluminum, or tackling different thicknesses in the same project, RayWeld keeps your workflow seamless.

Maximum versatility. Faster project turnaround. Consistent weld quality.

Lightweight Welding Torch

Our lightweight laser welding torch reduces operator fatigue and maximizes control, even during long shifts. With its ergonomic design and balanced feel, welders can achieve greater precision and consistency while working faster and more efficiently.

Experience the perfect blend of power and comfort—so every weld is as effortless as it is flawless.

The Future of Welding in Your Hands

Where productivity meets precision—redefining welding for the next generation.

Handheld laser welding technology eliminates the limits of traditional methods, delivering seamless welds, superior efficiency, and a streamlined workflow.

Step into the future of welding and unlock the full potential of your shop.

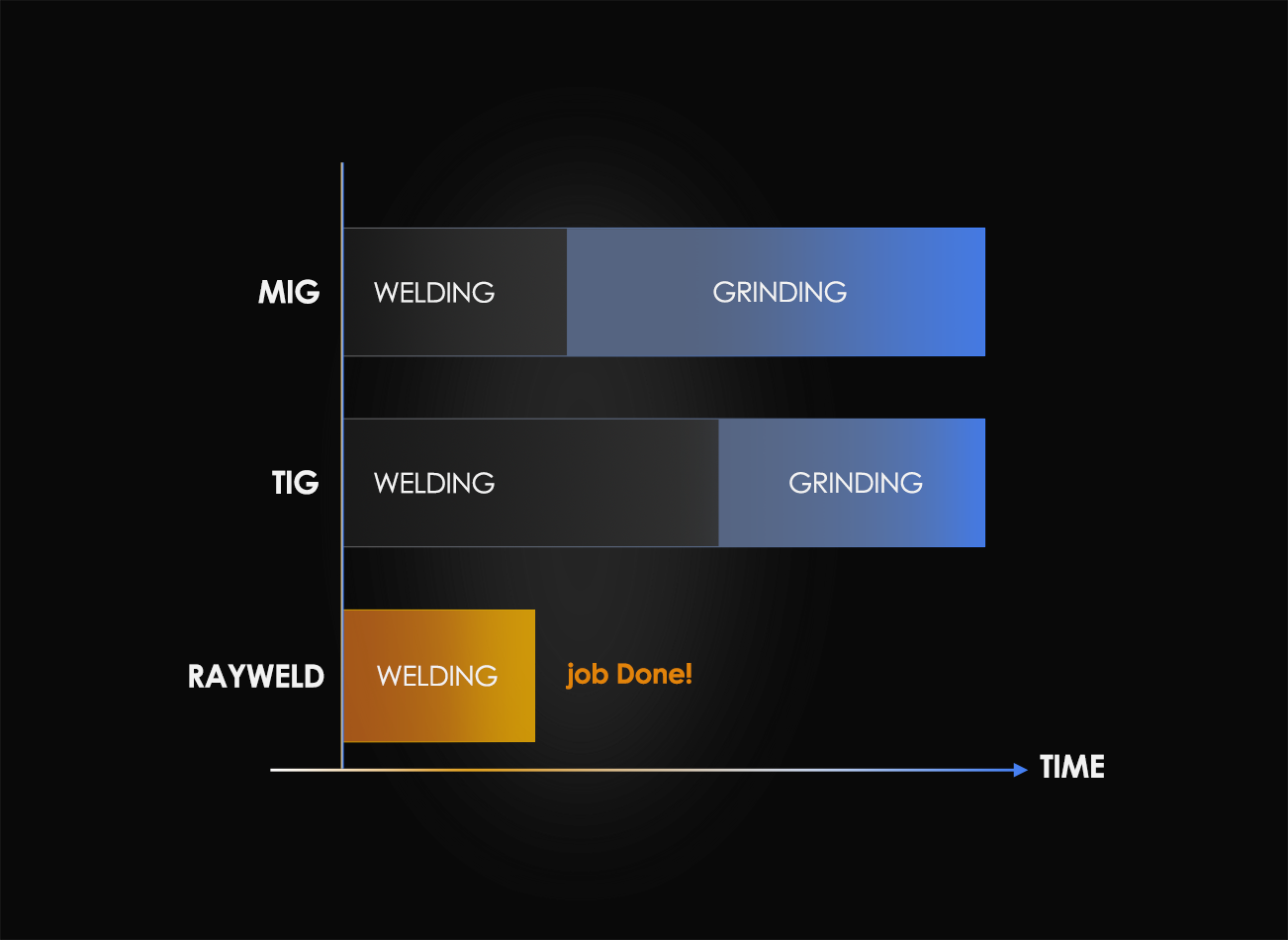

The End of Grind, The Start of Speed.

Rayweld isn’t just about welding up to 3X faster—it’s about eliminating the grind altogether.

Deliver flawless welds that look incredible straight off the torch, with little to no post-processing required.

Imagine the possibilities when all that extra time is back in your hands.